Sustainability

Economic

Business Ethics and Integrity

Establish corporate culture and risk management with integrity and discipline

Learn moreSupplier Management

Develop long-term partnerships based upon the principle of mutual benefit

Learn more

Business Ethics and Integrity

Establish corporate culture and risk management with integrity and discipline

Learn moreSupplier Management

Develop long-term partnerships based upon the principle of mutual benefit

Learn more

All members of CHC Group strictly abide by the Group’s procurement policies. Through supplier selection standards, risk identification, supplier management practices, supplier evaluations, the annual selection of excellent suppliers, and active management guidance for high-risk suppliers, the Group asks all suppliers to follow ethics code of conduct and procurement policies, as well as to comply with relevant domestic and foreign regulations regarding environmental protection, occupational safety and health, and human rights and labor rights. Making use of CHC Group’s business influence, the Group works together with supply chain partners to promote sustainable development. The audit results for the implementation of the Group's procurement policy in 2023 indicate that there were no significant violations and no instances of suppliers violating relevant regulations.

All of CHC Group’s suppliers sign the Declaration of Compliance & Questionnaire and assist with the assessment of the compliance with business ethics and determination of conflict of interest. The business ethics clause has been added to subcontracting and procurement contracts, which include anti-corruption, avoidance of conflict of interest, and rules for ethical management. Meanwhile, the procurement standards were amended to include the commitment to ethical management as a requirement for supplier evaluation and management, and to provide suppliers with consultation channels in order to help them understand the Group’s guidelines for business ethics. On the other hand, sustainability performance indicators, such as human rights, employee care, occupational safety measures, waste management, energy-saving measures, and integrity, are used for evaluating and managing suppliers' performance. Outstanding suppliers can earn additional points in the evaluation and increase their chances of winning bids, thereby promoting sustainability management throughout the supply chain.

| Supplier Registration | Supplier Qualification Assessment | Supplier Evaluation | |

|---|---|---|---|

| • Supplier data record filing • Five-Year Contract Performance Record • Receipt and Confirmation of Communication: o Corporate Culture Declaration o Business Execution Standards o Occupational Health and Safety Policy | • Contract Agreement Record • Performance Credit Evaluation Status • Interview with the Responsible Person • Financial Condition • On-site Survey • Regulations for the Management of Safety and Health on Construction Sites • Risk Identification Label • Peer Reviews | • During the Project, the Construction Unit Conducts Initial and Re-Evaluations of Suppliers: o A Grade – Recognized as a trustworthy and excellent supplier o B Grade – Recognized as a trustworthy supplier o C Grade – Suppliers requiring improvement and guidance o D Grade – Suppliers classified as non- cooperative and placed under observation |

|

| Suppliers are required to fill out a Supplier Information Card and a Five-Year Contract Performance Record according to the Supplier Screening Process and New Supplier Registration Agreement. The procurement unit verifies the information provided by the suppliers, communicates the company's corporate culture declaration, business execution standards, code of ethics and business conduct, and occupational health and safety policies. Once the verification is complete and the basic information is confirmed by the supplier's signature, the supplier is registered into the system. | For potential suppliers under consideration for contracts, the procurement unit will conduct risk identification operations based on company regulations and key risk management in various aspects of ESG (Environmental, Social, Governance). If the supplier is involved in major projects or raises safety and health concerns, due diligence investigations and site visits may be conducted as necessary, possibly in collaboration with relevant departments. ESG factors related to suppliers will be included in the selection assessment criteria. | During project execution, suppliers undergo assessment conducted by the site manager for initial evaluation. The project department supervisor performs a comprehensive review and final assessment, approving the evaluation results, which are then recorded in the supplier database system. We assess individual suppliers for financial capability, quality issues, safety and health deficiencies, project delays, non- performance risks, contract disputes within the supply chain, price fluctuations, shortages of goods and services, among other risks. We also emphasize human rights management, especially in occupational health and safety. If a supplier receives a D grade in safety and health assessments, they are required to complete improvements within a specified timeframe. Failure to meet these improvement deadlines will prompt the company to convene a review meeting to consider placing the supplier on a non- cooperation list. |

| Grade | Grade A | Grade B | Grade C | Grade D |

|---|---|---|---|---|

| Number of Suppliers | 25 | 1678 | 132 | 5 |

| Percentage | 1.4% | 91.2% | 7.2% | 0.3% |

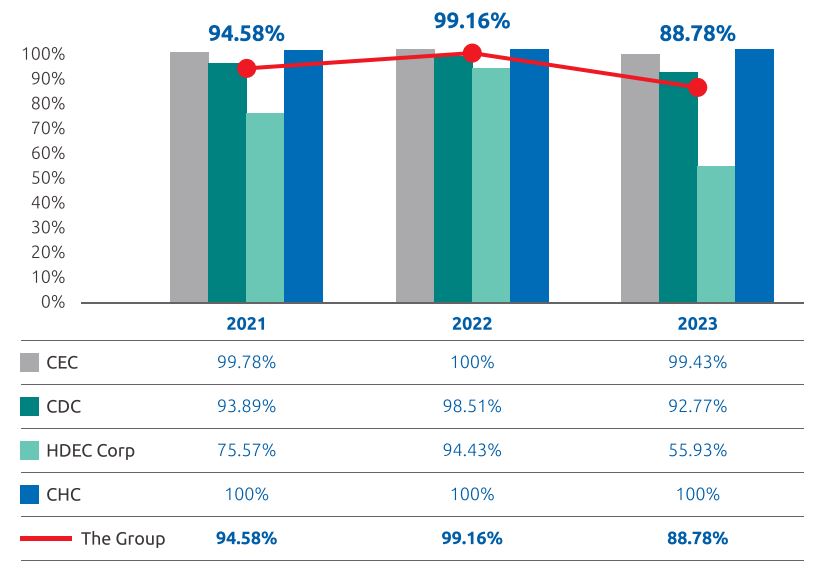

Supporting local procurement is a way of fulfilling corporate social responsibility. Except for the Environmental Project Development Business, where water treatment equipment is primarily supplied by foreign manufacturers and thus must be purchased from abroad, the rest of the Group members practice local procurement. In 2023, the CHC Group achieved an overall local procurement rate of 88.78%. Specifically, CEC, CDC, and HDEC Corp achieved local procurement rates of 99.43%, 92.77%, and 55.93%, respectively.